EPS Sandwich panel advantages

1.Water Prevention:

high-quality water-proof EPS.

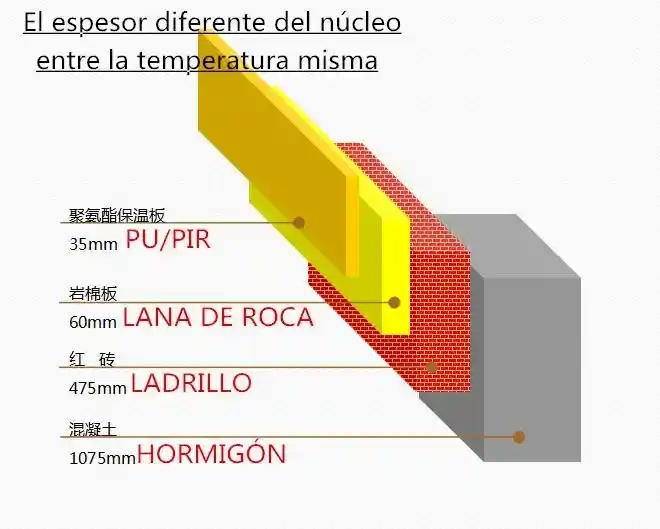

2.Thermal Insulation:

the low coefficient of heat conductivity and the excellent node design guarantee the sealing performance and the thermal insulation effect.

3.Sound insulation:

the sound absorption effect is good. The sound reduction factor is no less than 30dB. It can effectively reduce the interference of outside noise.

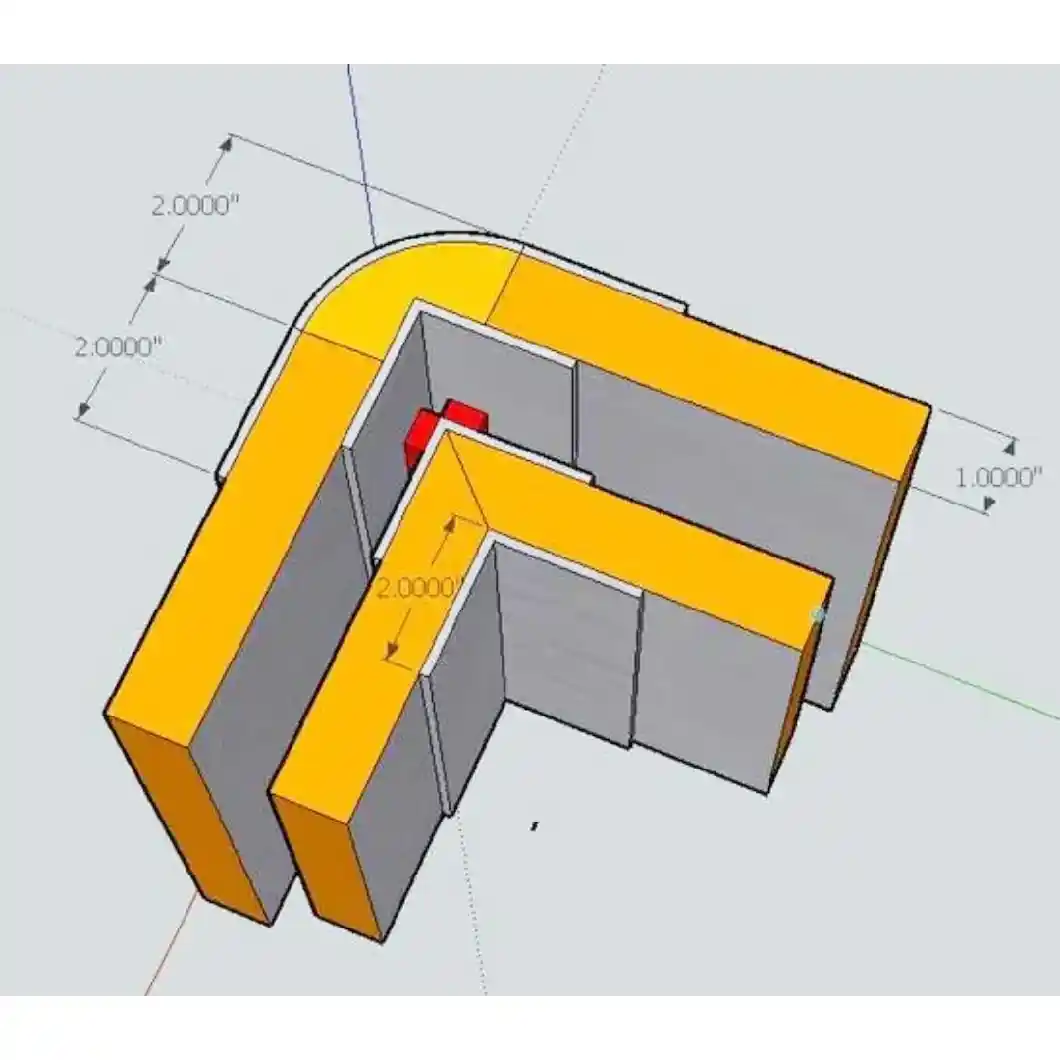

4.Solid:

the panel has high strength, unique double-support plug interface design and strong capacity in wind pressure resistance. It has strong strength to resist pressure and bearing, which can used as exterior protected construction and load-carrying construction.

5.Beautiful Design:

bright in color and attractive in appearance, there is no need to make the outer ornament. The panel adopts hidden-screw node design and has diversified panel effects.

6.Convenient Installation:

Easy, flexible and fast. Compared with civil construction, it can cut down over 40% construction

period.

PU /PIR/PUR/POLYURETHANE SANDWICH PANEL

| Painting of steel plates | PVDF, SMP, HDP, PE; The top painting should be above 25μm. |

| Galvanized layer of steel plates | Exterior plate: 55% Aluzinc above 100G/M³or Zinc coating above150G/M³; Inner plate: 55% Aluzinc above 70G/M³or Zinc coating above 100G/M³ |

| Thickness of steel plates | 0.4mm-0.8mm. |

| Thickness of core | 50mm/75mm/100mm/120mm/150mm. |

| Density of core | 40-50kg/m³ |

| Effective width | 930mm 1000mm |

| Panel Length | According to customers' request |

ROCKWOOL SANDWICH PANEL

| product name | Rockwool sandwich panel |

| Painting of steel plates | PVDF, SMP, HDP, PE; The top painting should be above 25μm. |

| Galvanized layer of steel plates | Exterior plate: 55% Aluzinc above 100G/M³or Zinc coating above150G/M³; Inner plate: 55% Aluzinc above 70G/M³or Zinc coating above 100G/M³ |

| Thickness of steel plates | 0.4mm-0.8mm. |

| Thickness of core | 50mm/75mm/100mm/120mm/150mm. |

| Density of core | 60/80/90/100/120kg/m³ |

| Effective width | 950/980/1150mm |

| Panel Length | According to customers' request |

As the world’s best thermal insulation material, polyurethane is widely used in various fields for its excellent performance such as environmental protection and light weight, and in recent years, it has been used more and more in the cold chain industry.

Polyurethane composite panels are also called PU sandwich panels.

The composite panel with polyurethane as the core material is composed of the upper and lower layers of color steel plate and the intermediate foamed polyurethane, which adopts the world’s most advanced six-component online automatic operation mixing and pouring technology, which can complete the proportioning and mixing process of the social batching center or factory online at one time, and can be adjusted at will according to the temperature online, so as to produce a unique high-strength, energy-saving, green and environmentally friendly building panel.

Polyurethane sandwich panels are widely used in large industrial plants, cold storage, garages, mobile homes, exhibition halls, exhibition halls, gymnasiums, shopping centers, airports, power plants, villas, hospitals, strata and high-rise office buildings and other fields.